In comparison with other mechanical

methods of metal working electro-erosion machining is more economical. The

technology allows to produce the articles with the most complex spatial contour

of machining and obtains the highest quality of machined metal surface,

including heightened hardness – the parts of blank dies, moulds, matrixes,

dies, form tools, templates and etc.

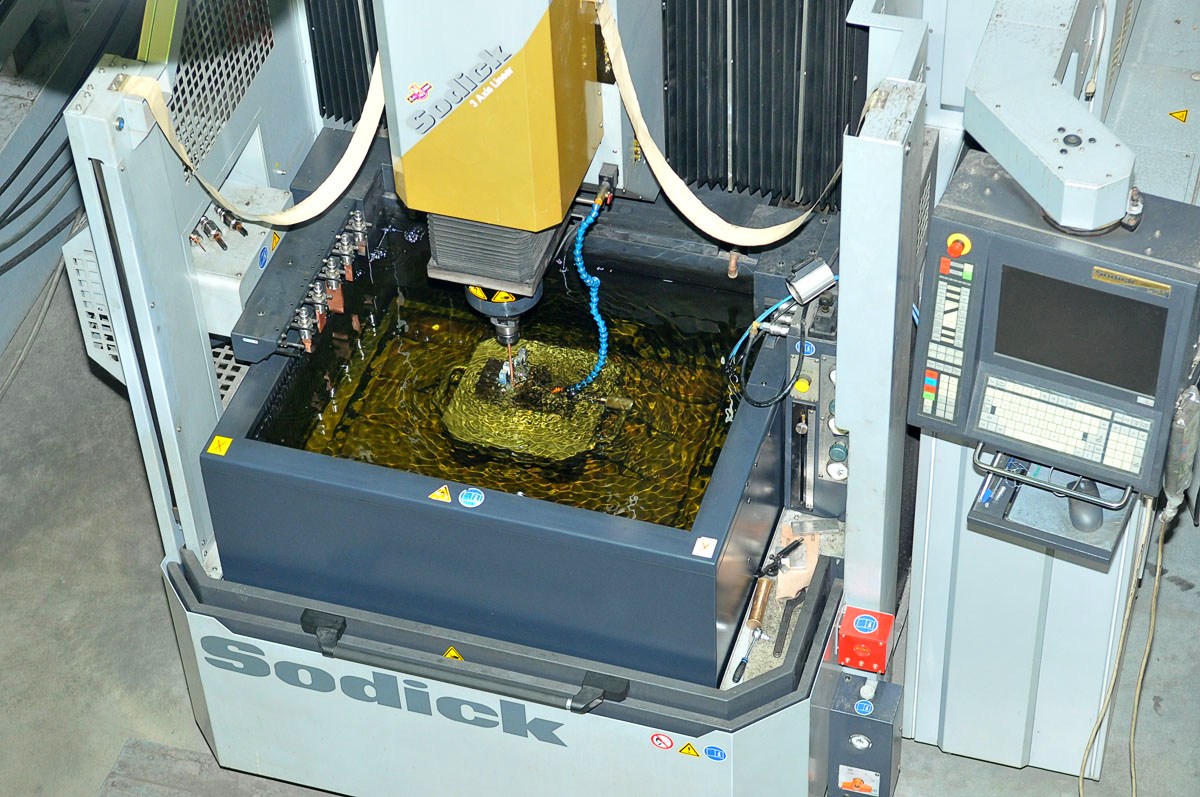

Electro-erosion area of «Polymer-Electron»

plant is equipped with machines of leading world producers: - SODIK AQ537L, JAPAX LS- 500X

electro-cutting machines; - SODIK AQ 55L, JAPAX DS-45HC electro-broacing

machines; - AGIE 4U electro-erosion machine; - SODIK КС1

super drill; - EYAPT JAPAX programmer; - EROWA, FARO measuring complexes.

Automated monitoring and control system of

electro-erosion area works on the base of EYAPT JAPAX programmers and EROWA

PRESET 3D MAN control-measuring complex.

EROWA PRESET 3D MAN measuring complex,

except spatial 3D scanning of complex surfaces, allows to fulfill the

correction of mechanical trajectory of a tool or electrode on NC-machines in

real time.

Tool production of «Polymer-Electron»

plant offers its services in finishing and repair-erosion working to the

interested enterprises and organizations. If you are interested in our offers, details of your order you can send by email office@polymer.electron.ua, b.olenyuk@polymer.electron.ua. | |

| |

| |

|